Providing Custom Sheet Metal Fabrication Services in China

The fabrication of custom sheet metal has become increasingly important to a variety of industries, including construction and automotive. Precision and tailor-made metal components have revolutionized manufacturing, giving businesses the ability to meet their unique requirements with flexibility. This article explores the significance, applications, benefits, and the process involved in custom sheet metal fabrication service, which opens up endless possibilities for a wide variety of industries.

The custom fabrication of sheet metal

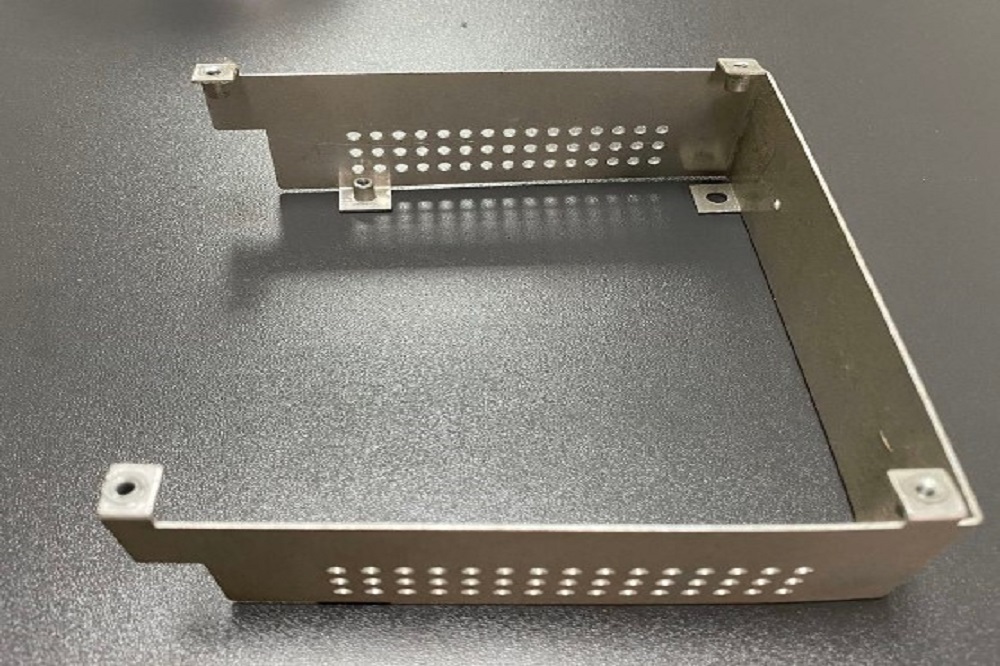

Fabrication of sheet metal into specific components and structures based on the needs of individual clients is known as custom sheet metal fabrication. It involves cutting, bending, welding, and assembling metal sheets into intricate and precise parts that can be used in a variety of different applications through the process of cutting, bending, welding, and assembling. There are many types of components available, such as brackets and enclosures, to machine parts and prototypes.

Industry-wide Applications

A custom sheet metal fabrication process is widely used in the construction industry to make building components such as roofing materials, wall panels, gutters, and structural supports. Despite harsh environmental conditions, it is durable, strong, and versatile.

The sheet metal fabrication industry plays a vital role in the manufacturing of car bodies, chassis, and interior and exterior components in the automotive industry. As a result of this process, vehicles are not only aesthetically pleasing, but also safe and reliable due to its precision and consistency.

A cornerstone of aerospace manufacturing is custom sheet metal fabrication. This process facilitates the manufacture of lightweight yet robust components, crucial for the construction of aircraft and spacecraft. In order to achieve the desired strength-to-weight ratio, it is necessary to work with a variety of alloys and metals.

The electronics industry relies on custom sheet metal fabrication to create enclosures, cabinets, and housing for various devices and equipment. These parts not only provide protection but also aid in heat dissipation and electromagnetic shielding.

Medical equipment, instruments, and specialty parts are manufactured using custom sheet metal fabrication. Medical equipment, instruments, and specialized parts contribute to improving patient care and treatment outcomes.

Custom sheet metal fabrication is ideal for solar panels, wind turbines, and other renewable energy systems because of its durability and weather-resistance.

The benefits of custom sheet metal fabrication

A major benefit of custom sheet metal fabrication is that it offers tailored solutions. Businesses are able to order specific designs and dimensions, ensuring that the end product exactly meets their needs.

It's common belief that mass-produced products are more cost effective than custom made ones. However, custom fabrication can often be more cost-effective by eliminating excess inventory and reducing material waste.

Custom sheet metal fabrication requires advanced machinery and skilled artisans to ensure high quality and precision. This ensures that the final product meets industry standards and customer expectations.

Despite being a highly detailed process, custom fabrication can often be completed in a much shorter period of time than traditional manufacturing methods. Advanced technologies enable businesses to meet tight deadlines more readily.

Custom sheet metal fabrication allows businesses to work with a wide variety of metals and alloys, including steel, aluminum, copper, brass, and more. Due to this diversity, components can be designed with varying mechanical properties based on their application requirements.

Custom Sheet Metal Fabrication

There are several essential steps involved in the fabrication of custom sheet metal components, each contributing to their precision and high quality:

Detailed design and engineering is the first step in the process. Clients collaborate with fabrication experts to conceptualize the component, considering its intended use, dimensions, materials, and any additional features.

During the material selection stage, factors such as strength, corrosion resistance, weight, and cost are taken into consideration, according to the project requirements.

A variety of techniques, such as laser cutting, plasma cutting, or water jet cutting, are used to cut the sheet metal after the design has been finalized and the material selected.

Cutting and bending the metal sheets requires the use of specialized machines and tools to bend and form them into the required contours and angles.

Several parts of a component need to be welded together, and skilled welders ensure seamless connections. All parts are carefully integrated to create the final product. Get more info about sheet metal fabrication service.

Surface treatments like painting, powder coating, or anodizing are typically applied after fabrication has been completed to improve the component's appearance and functionality.

In conclusion

The ability to fabricate unique, high-quality sheet metal components that perfectly match a company's needs has made custom sheet metal fabrication services an indispensable asset across a diverse range of industries. With advanced manufacturing technologies and the ability to work with multiple metals, precision and efficiency are unparalleled. Custom sheet metal fabrication continues to drive innovation and progress across a wide range of industries, from construction to renewable energy. With this bespoke approach to metalworking, industries can achieve new levels of success, ensuring that their projects and products stand out in an increasingly competitive global marketplace.

Comments

Post a Comment